On-line installation, mechanical flow switch, for liquid or gas medium. Sturdy plastic, aluminum or stainless steel case is optional. Minimal pressure loss, good repeatability, anti-fouling ability, complete isolation between mechanical and electronic parts, suitable for low flow economy. 3 times the piston stroke of the original RST-HS to make the setting accuracy more accurate. With a switch setting scale, users do not need to set in the field. LED display switch status, double switch output optional. Gas-liquid dual purpose, industrial automation/mechanical equipment/air compression industry/refrigeration and air conditioning.

II.Technical parameters

|

Setting range: |

See parameter table |

RST-HS100...GS Material: |

Case: POM plastic |

|

Accuracy: |

±5% total range |

|

Piston: POM plastic, stainless steel |

|

Hysteresis: |

Depending on the switch, the amount is small 0.5L/Min |

|

Spring: stainless steel |

|

Switch setting scale: |

Sealing in water medium, temperature 20℃, horizontal installation state |

|

Seal: NBR |

|

|

The calibration. Installation position, medium and temperature changes will have a slight effect on the switch value. |

RST-HS100...GLmaterial: |

Shell:Anodic alumina |

|

|

|

|

Piston:POM plastic, stainless steel |

|

LED display |

DC power supply LED display switch status, AC no LED display. |

|

Spring: Stainless steel |

|

Wiring: |

Connector |

|

Seal: NBR |

|

Output: |

Spring switch, capacity 24VDC/250VAC, 100mA |

RST-HS100...GB material: |

Shell:Stainless steel |

|

Pressure: |

50 bar type (aluminum), 100 bar type (stainless steel) |

|

Piston:POM plastic, stainless steel |

|

Average pressure loss: |

0.3bar(at 25L/min) |

|

Spring: ?Stainless steel |

|

Medium temperature: |

maximum 90℃ |

|

Seal:NBR |

|

Protection level |

IP65 |

|

|

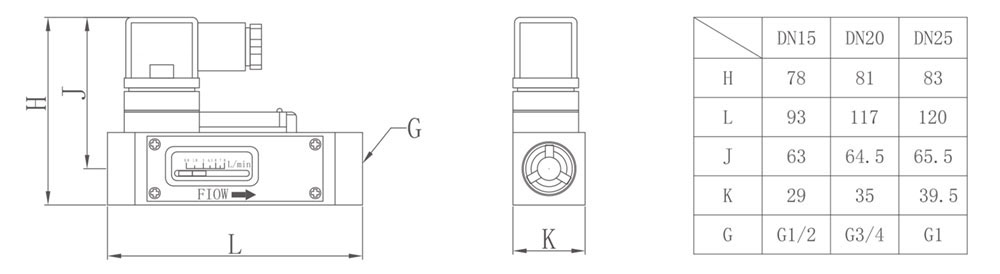

III.Product size

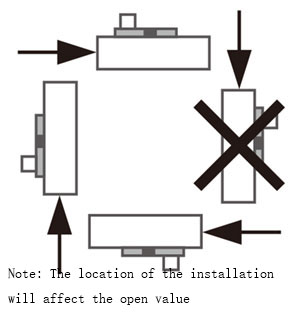

IV.Installation instructions

V.Selection table