I. Product introduction

Rst-01b series flow switches adopt target sensors, which can be used for flow control or alarm protection in water cooling system or lubricating oil circuit system. Relays may also be used to detect and observe liquid flow, generally used in air conditioning, water supply, and to sense changes in the flow of liquid through pipes, such as water, ethylene, glycol, or other non-hazardous liquids, typically used in areas requiring interlocking or "cut-out" protection. The set value is adjustable, which can be adjusted by users according to their needs.

II. Product selection

|

Model |

Product specification |

|

RST-01Bb |

Joint, target rod (brass), plastic parts (flame retardant ABS), and other parts shall be made of 304 stainless steel (no electroplating parts) |

|

RST-01BH |

Joint, target rod (brass), plastic parts (flame retardant ABS), and other parts shall be made of 304 stainless steel with high temperature resistance of 125 ° C |

|

RST-01BS |

Joints, target rods and bellows shall all be made of stainless steel (S316S304), plastic parts (flame retardant ABS, stainless steel), and (non-electroplated parts). |

|

RST-01BO |

Joint, target rod (brass), plastic parts (flame retardant ABS) and other parts shall be made of 304 stainless steel (electric parts shall be OMRON from Japan). |

|

RST-01BN |

Joint (reinforced engineering plastics) target rod (brass), plastic parts (flame retardant ABS), other parts shall be made of 304 stainless steel |

|

RST-01BX |

Small size |

III.Technical parameters

|

Interface: |

1/2"、3/4"、1" |

|

Adjustment range: |

6-1800L/min |

|

Pressure: |

1.6MPa |

|

Medium temperature: |

0℃~90℃ |

|

Ambient temperature: |

-40℃~60℃ |

|

Electric shock capacity: |

A.C.250V10A(resistance) |

|

|

Switching contact one pay (normally open and normally closed) |

|

Material: |

Brass, stainless steel |

|

High temperature and high pressure: |

4.2mpa |

|

Medium temperature:0℃~320℃ |

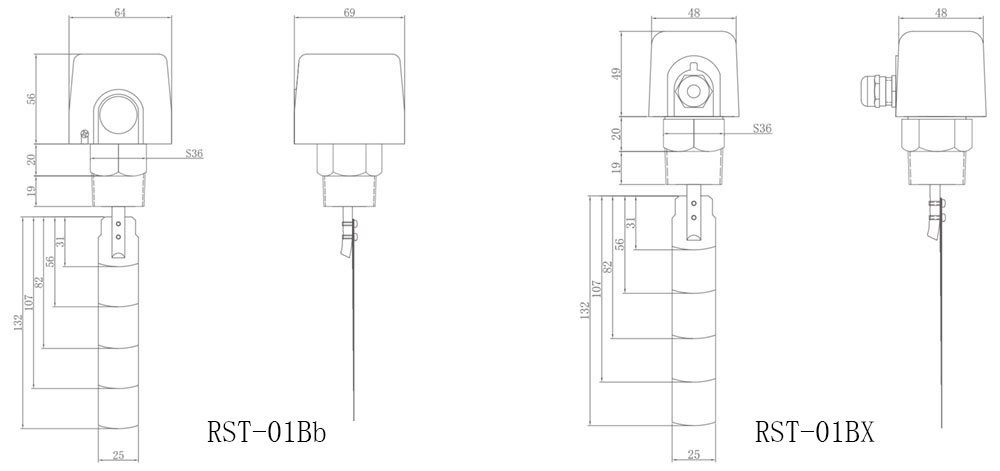

IV.Product size

V.Installation instructions

1. Open the flow switch housing;

2. The switch has been set at about the minimum flow value when leaving the factory. Increase the flow setting value and turn the adjusting screw clockwise (1);

3. Press the target to check whether the microswitch can work normally. Too many counterclockwise adjusting screws may cause the failure of the flow switch;

4. After installation, please check the lever by pressing the flow switch several times. Once it is found that there is no "click" sound when the lever returns, turn the adjusting screw clockwise until there is "click" sound when the lever returns;

5. Do not remove the fixing clamp of the adjusting screw, otherwise the flow adjusting screw will fail;

6. Adjustment screw for lacquer seal is only for factory to adjust flow switch state, do not change or adjust;

7. Three working cycles shall be observed to ensure that the switch and the system connected to it operate normally, and the switch housing shall be covered in time.

VI.Attention

1. Please carefully check the flow switch before installation. The package should be complete and the appearance should be free from damage and deformation. If you have any questions, please contact the manufacturer.

2. The flow switch can be installed in horizontal pipe or vertical pipe with the direction of liquid flow upward, but not in pipe with the direction of liquid flow downward. Gravity should be taken into account when installing in a pipe in the flow direction of liquid.

3. The flow switch must be installed on a straight line with a straight stroke of at least 5 times of pipe diameter on both sides. At the same time, it should be noted that the direction of liquid flow in the pipe must be consistent with the arrow direction on the switch housing, and its wiring terminals should be in a position easy to be connected. (figure 1)

4. During installation and wiring, please pay attention to the following matters:

5 Absolutely forbid the spanner to collide with the switch bottom plate, resulting in flow switch deformation failure;

6. In order to avoid electric shock and damage to the equipment, the power should be cut off when wiring or debugging;

7. When wiring, it is absolutely forbidden to adjust other screws except microswitch wiring terminals and ground screws.

8. Special grounding screws must be used for wiring, and installation screws cannot be removed at will, otherwise the controller will become deformed and fail;

9. The target of the flow switch should not be in contact with the inner wall of the pipe and other restrictors in the pipe, otherwise the switch could not be reset normally.

Contact: Miss Zhang

Phone: 18816633390

Tel: 0532-86888236

Email:

Add: No.7, Siliu Middle Road , Licang District, Qingdao City, Shandong Province, China